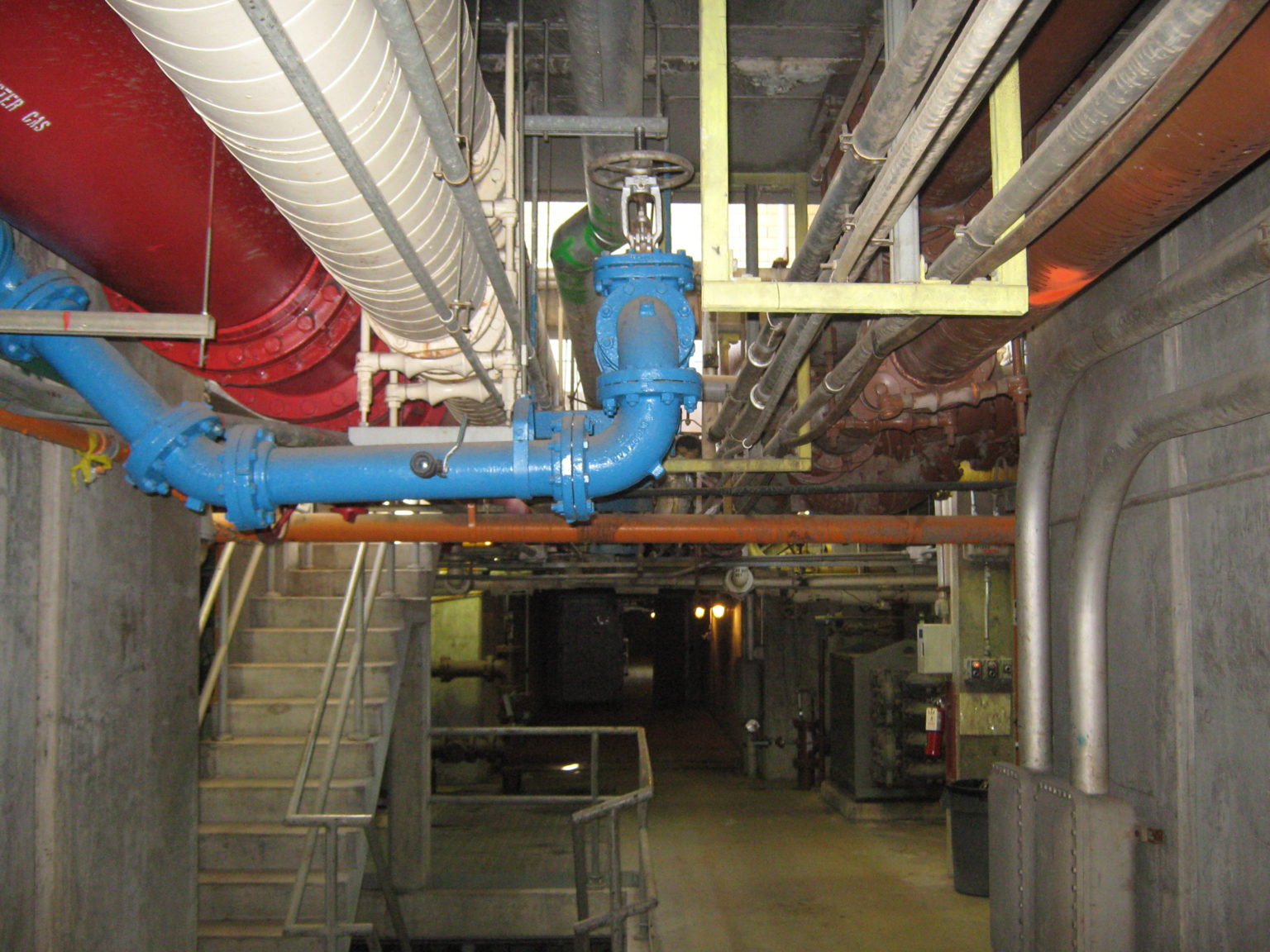

Mill Creek WWTP Anaerobic Digester Conversion to Mixing/Holding Tanks

CINCINNATI, OHIO

Mill Creek WWTP Anaerobic Digester Conversion to Mixing/Holding Tanks

Project never constructed due to funding.

Client: MSD of Greater Cincinnati

Project Overview

Ribway was selected by MSD of Greater Cincinnati as the prime consultant for engineering design services for this $12 Million solids handling and improvement project at its 430 mgd Mill Creek WWTP. The project is a part of the Solids Handling Phase I Improvements which will include the provision of new sludge dewatering wells and feed pumps for the existing centrifuges. Design engineering services included:

- Field investigations

- Preliminary design engineering

- Preparation of a Design Report with evaluations

- Recommendations and cost estimates

- Detailed design engineering and preparation of plans and specifications for construction

An asbestos and hazardous material survey, geotechnical services and environmental soils investigation services were also performed during the design phase.

The project was set to include the following improvements:

- Demolition of eight (8) existing anaerobic digesters

- Demolition of four (4) digester control buildings, waste gas burners, and miscellaneous digestion equipment

- Conversion of four (4) existing digesters to Sludge Holding Tanks (SHTs)

- New sludge pumping facilities

- Complete renovation of two (2) four-story digester control buildings

- Major electrical and mechanical improvements

The existing digesters are 110 feet in diameter, 45 feet deep and buried about 30 feet below grade. Demolition of the digesters and control buildings were to be performed to approximately 12 feet below grade. The four (4) new Sludge Holding Tanks were to be equipped with fixed aluminum geodesic dome covers and a submersible mixing system. Two (2) sludge transfer pumps were to transfer sludge from each SHT to sludge dewatering wells for conveyance to the dewatering centrifuges. Renovations to the digester control buildings were to include new roofing, doors, windows, railing, and concrete and masonry repairs. New heating and ventilation systems were to also be provided. Electrical improvements were to include the construction of a new Electrical Room with multiple MCCs and power distribution equipment for process equipment, interior and exterior lighting. Process operations were to be fully automated and controlled through a PLC System.